We, Ohashi Tekko Vietnam is Parts Manufacturer mainly Press & Cation ED Coating.

TEL:0211.3888.084

Cation ED coating line

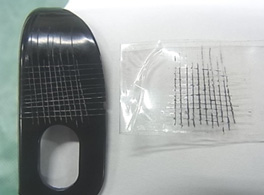

Cation ED coationg parts

Cation ED coating

The cation electrodeposition coating can create a high quality coating. The process is products are immersed into cabins, it is deposited by current flows between products is a cathode (−) and inside cabin is an anode (+).The cation ED coating can make products coated a uniform thickness and the layer has excellent rust preventation after the quenching process.Also due to excellent corrosion resistance, the cation ED coating is used many other applications.

Specification

・Manufacturing Consecutively and adapt for mass production

・Low paint loss and high productivity

・No danger of catching fire due to water solubility

・Naturally friendly because of almost using no organic solvents

・High quality coating even coating with complex shapes and structure

Main usage

・Auto parts ・motorcycle parts

・Electrical appliances ・Agricultural machines

・Electronic parts ・Steel furniture

・Industrial device

※Something to metal (conductive) products can be painted by cation ED coating method.

Available size: (Max) 550mm×1000mm×200mm

Compering Cation coating and other coatings(with our company)

Test item/Method |

Cation ED coating |

Zincing |

Powder coating |

|---|---|---|---|

Environment |

◎ |

× |

△ |

Complex shape |

◎ |

〇 |

〇 |

Rust corrosion preventive |

◎ |

〇 |

◎ |

Uniformity |

◎ |

△ |

× |

Cost |

〇 |

〇 |

× |

Quality result

Product:BracketMaterial name:Sakusedo 80#V-ERD

|

|

Thickness(㎛) |

Salt spray test

|

Adhesion

|

|---|---|---|---|

Standard |

20±5 |

Rust width:No more than 2mm

|

Not peel off |

Result |

20.07~22.43 |

Rust width: 0.4mm

|

No peel off |

Judge |

〇 |

〇 |

〇 |

・There is nothing wrong with all tests for thickness, salt spray and adhesion.

Leadtime

・It takes about 3 days from coating and inspection to delivery

we would like to meet customers request

バナースペース

Ohashi Tekko Vietnam

Lot B, Road No. 5, Binh Xuyen Industrial Park, Binh Nguyen Commune, Phu Tho Province, Vietnam

TEL :0211.3888.084

FAX :0211.3888.085